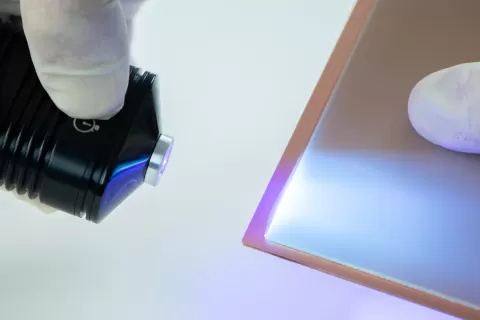

Master Bond LED415DC90Med is a one part system that cures rapidly upon exposure to LED light at 405 nm followed by heat curing at 90-95°C for 30-45 minutes. This fast curing system is not oxygen inhibited and can cure up to 6 mm deep or in cross section. This unusual curing profile allows the system to be used for side bonding. Side bonding refers to a situation where the LED is applied between two opaque substrates and the light is exposed to the adhesive from a side angle and not through the substrate, which is more typical. The unusually deep penetration in cross section offered by LED415DC90Med allows it to partially cure enough to fixture the two substrates.

The recommended intensity of the light source should be 2-4 watts/cm2, but there are some variables to consider with speed of the LED curing process. These include the intensity of the light source, the thickness of the layer, and the width of the cross section that is being cured.

LED415DC90Med bonds well to a wide variety of substrates including plastics, glass and metals. The system has good resistance to medical sterilants such as gluteraldehyde, peracetic acid, as well as EtO, gamma radiation, among others. It is a reliable electrical insulator with a service temperature range of -80°F to 350°F. Additionally, it can withstand rigorous thermal cycling, mechanical shock and vibration. The main attraction of this one part system is its rapid cure that utilizes LED light for the initiation of polymerization, followed by completion of curing by heating. The combination of fast, easy processing and good physical strength properties, along with ISO 10993-5 compliance, opens creative new horizons for using adhesives in medical device manufacturing.

Product Advantages

- One component system

- Fast dual curing system, LED light and heat

- Excellent strength properties, especially lap shear

- Can cure in cross sections 4-6 mm

- Meets ISO 10993-5