EP30D-7

Flexibilized, two component urethane-modified epoxy system

Key Features

- Superior toughness

- Ambient temperature curing

- Superb resistance to thermal cycling

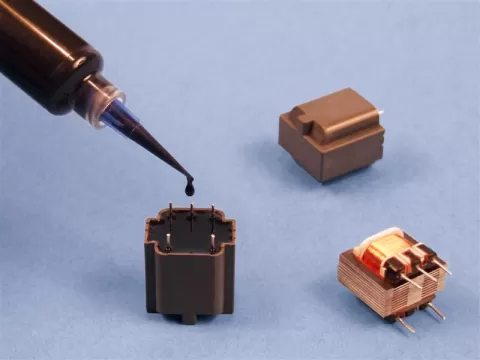

- For bonding, sealing, coating and encapsulation

- Urethane-modified epoxy

- Exceptional abrasion resistance

Typical Properties

Viscosity

Part A: 40,000-70,000 cps, Part B: 300-600 cps

Cure Schedule

At 75°F, Master Bond EP30D-7 cures in 48 to 72 hours. Faster cures can be realized at elevated temperatures, e.g., 2-3 hours at 200°F.

Hardness

90-100 Shore A

Service Temperature Range

-100°F to +250°F

Dielectric Strength

450 volts/mil

Elongation

90-110%

Imagen