EP4EN-80

One component flowable epoxy for bonding and small encapsulation applications with a curing schedule at 80°C to 85°C

Key Features

- Thermally conductive, electrically insulating

- Ultra fine particle size

- Can cure up to 1/4 inch thick

- High modulus and compressive strength

Typical Properties

Viscosity

600-1,800 cps

Cure Schedule

90 minutes at 65°C plus 30 minutes at 80-85°C

Hardness

85-95 Shore D

Service Temperature Range

-58°F to +302°F

Dielectric Constant

4.4

Thermal Conductivity

5.2-5.9 BTU•in/(ft²•hr•°F) [0.75-0.85 W/(m•K)]

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Vídeo

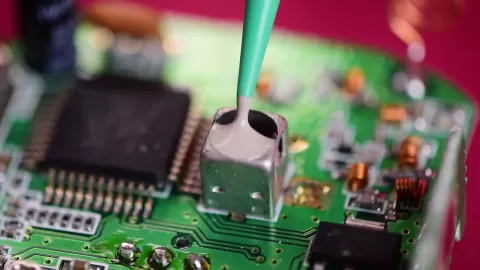

How Do You Use EP4EN-80 for Potting & Encapsulation Applications?

With its thin bond line thickness and low viscosity, EP4EN-80 is ideal for bonding, encapsulating and potting applications. Watch a real-life demonstration of how this epoxy compound can be used while observing its flowability and ease of use.