LED415DC90

One component, flexibilized LED curable system

Key Features

- Cures rapidly with LED light

- Secondary heat cure at 90-95°C

- Can cure up to 6 mm deep or in cross section

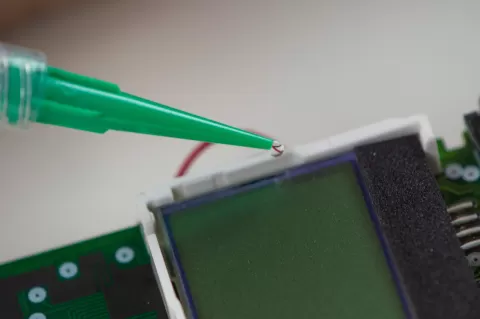

- Formulated for “side bonding” applications

Typical Properties

Viscosity

25,000-250,000 cps

Cure Schedule

Cures rapidly upon exposure to LED light at 405 nm followed by heat curing at 90-95°C for 30-45 minutes

Hardness

85-90 Shore D

Service Temperature Range

-80°F to +350°F

Tensile Modulus

450,000-550,000 psi

Volume Resistivity

>10¹⁴ ohm-cm

Image

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863