Master Bond Polymer System EP42HT-2FG is a room temperature setting, two component epoxy adhesive, sealant and coating specially formulated for food applications. It has been independently tested and certified by one of the nation’s leading laboratories to meet the most stringent requirements of FDA CFR 175.300. It was additionally assessed and found to meet the toxicological requirements of the NSF/ANSI 51 (2009) Standard for Food Equipment Materials as defined in section 4.1.

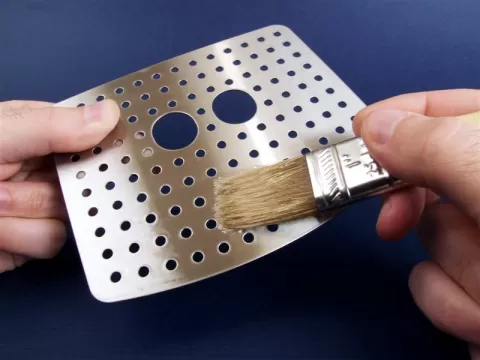

EP42HT-2FG has wide applicability in the food industry. As an adhesive and sealant, it is well suited for bonding metals, plastics, rubbers and other substrates common to the manufacture of food service equipment. As a coating, it can be used on storage tanks, bins, hoppers and many other types of containment vessels. It also has superb electrical properties, outstanding flowability and is an excellent system for potting and encapsulation. EP42HT-2FG has exceptional resistance to heat, boiling water, fats, oils and many other chemicals, as well as steam and radiation.

EP42HT-2FG has a mix ratio of 100 to 30 by weight. The color of Part A is clear and of Part B is amber. The system can cure in 3-4 hours at 150-250°F. However, to optimize properties, the recommended cure schedule is overnight at room temperature followed by a post cure of 3-4 hours at 150-250°F. The service temperature range of EP42HT-2FG is -60°F to +450°F. For the purposes of FDA CFR 175.300, testing was done at the temperatures specified in the test protocol.

Please note that while EP42HT-2FG has met or exceeded the FDA and NSF/ANSI standards listed above in laboratory testing, it is essential that the end-user consult with their own legal and technical experts, and perform their own testing as needed, to ensure the product will perform as expected under field service conditions. Full documentation of all testing protocols and results are available on request.

Product Advantages

- Strong bonds to metals, plastics, rubbers and ceramics

- Excellent resistance to fats, oils, acids, alkalis and many solvents

- Resists high temperature boiling water, radiation, chemicals, steam and frozen storage conditions

- Contains no solvents or diluents

- Low viscosity and superb flowability

- Superior electrical insulation properties

Frequently Asked Questions

Which food grade specifications does EP42HT-2FG meet?

EP42HT-2FG complies with the FDA 175.105 and 175.300 standards. Master Bond has independently tested this epoxy with a leading laboratory to ensure that it meets the stringent FDA CFR 175.300 food grade testing requirements, as well as NSF/ANSI 51 (2009) Standard for Food Equipment Materials as defined in section 4.1. Master Bond can provide the toxicological review and test report upon request.

Is EP42HT-2FG rated for direct contact with food?

Although EP42HT-2FG is not rated or qualified for applications involving direct food contact, it is suitable for sustained use in indirect food contact type applications.

Can EP42HT-2FG be used to repair items and equipment in a home kitchen?

No. EP42HT-2FG is only intended for industrial bonding, sealing, coating and potting applications and is not suitable for home use. This epoxy requires heat curing (~150-200 F) for at least 3-5 hours, and we highly recommend the use of industrial ovens for the curing process.

Is EP42HT-2FG rated for contact with potable water?

No. EP42HT-2FG is not rated or qualified for use in potable water applications.

What types of chemicals can EP42HT-2FG resist?

EP42HT-2FG offers superior resistance to many solvents, bases/alkalis, boiling water/steam, fats and oils.

Although EP42HT-2FG has passed FDA and NSF/ANSI standards, how important is it for the end user to perform further testing on the final device?

It is the end user’s responsibility to consult with the appropriate agencies as well as their own legal and technical experts, in order to qualify the EP42HT-2FG in the context of their application, and obtain the necessary approvals for the final device.