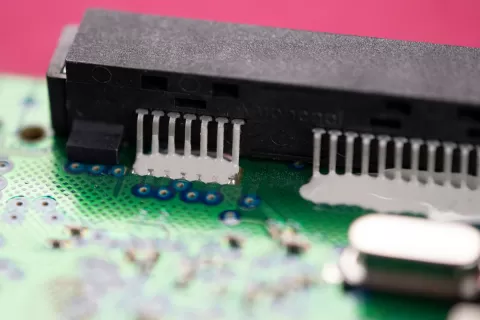

Master Bond EP4UF-80 is a one component, low viscosity epoxy primarily for underfill applications, that can also be used as an adhesive. It has good flow properties and will cure at elevated temperatures with a minimum of 80°C. It is shipped at -40°C and should be stored at that temperature. Once removed from the freezer, for optimum results, use the epoxy within 6 hours. Any remaining material should be discarded. Curing is simple and straightforward; 30-60 minutes at 80-85°C, or 15-30 minutes at 90-95°C. EP4UF-80 has a thermally conductive, electrically insulative filler material with ultra small particle sizes. This allows EP4UF-80 to be used as an underfill in spaces as small as 10-15 microns wide. As an underfill system, EP4UF-80 has high mechanical strength properties, outstanding dimensional stability and low shrinkage upon curing.

EP4UF-80 is a highly useful thermally conductive adhesive. It bonds well to a variety of substrates such as metals, composites, ceramics and many plastics. Because the particles are so small, it can be applied in thin bond sections. This, in effect, lowers the thermal resistance and increases the heat transfer properties of the system. For example, with a typical thermally conductive filler, a reasonable bond line thickness is about 50 microns. In this scenario, the thermal resistance would be 50-100 x 10-6 K•m2/W. However, when an epoxy such as EP4UF-80 is applied, the thin bond line lowers the thermal resistance to 10-20 x 10-6 K•m2/W. This is a big positive in managing heat related issues. EP4UF-80 will resist waters, oils and fuels. Its color is gray. The service temperature range is -50°C to +150°C. The system is a highly effective thermal interface material for bonding and underfill applications in microelectronic packaging and assembly.

Product Advantages

- Single component; no mixing needed

- Rapid curing with versatile cure schedules

- Can be used as an underfill for very tight spaces

- Small particle size lowers thermal resistance

- High modulus