EP13LTE

One component, heat curing epoxy for structural bonding applications featuring low coefficient of thermal expansion

Key Features

- High temperature resistance

- Excellent adhesion to a variety of substrates

- Passes NASA low outgassing tests

- Electrically insulating/thermally conductive

Typical Properties

Viscosity

paste

Cure Schedule

300-350°F for 1-2 hours; post cure of 2-3 hours at 350-400°F

Hardness

85-95 Shore D

Service Temperature Range

-60°F to +500°F

Coefficient of Thermal Expansion

15-20 X 10⁻⁶ in/in/°C

Glass Transition Temperature (Tg)

155-160°C

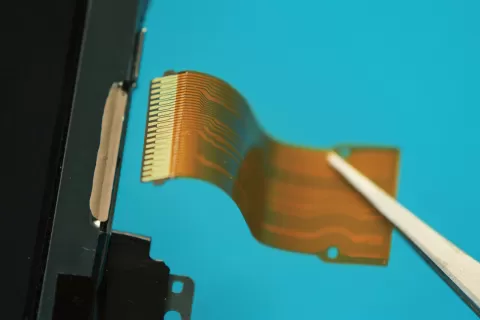

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863