EP30FL

Two component epoxy system for high performance potting, casting, bonding and sealing

Key Features

- Exceptionally low viscosity

- Good flexibility

- Cures at room temperature

- Cryogenic serviceability

Typical Properties

Viscosity

Part A: 700-1,200 cps, Part B: 60-120 cps

Cure Schedule

12-24 hours at ambient temperatures followed by 2-3 hours at 140-170°F

Hardness

25-40 Shore D

Service Temperature Range

4K to +250°F

Dielectric Constant

3.83

Refractive Index

1.57

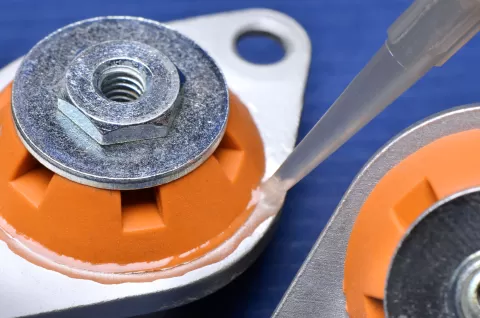

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863