EP40NDMed

Two component, medical grade epoxy with good toughness and paste consistency

Key Features

- Convenient handling

- Good bond strength in shear and peel modes

- Exceptional adhesion to polycarbonates and acrylics

- Meets ISO 10993-5

Typical Properties

Viscosity

Part A: 50,000-100,000 cps, Part B: paste

Cure Schedule

overnight at 75°F followed by 2-3 hours at 120°F to 150°F

Hardness

50-60 Shore D

Service Temperature Range

-100°F to +250°F

Elongation

80-90%

Volume Resistivity

>10¹⁵ ohm-cm

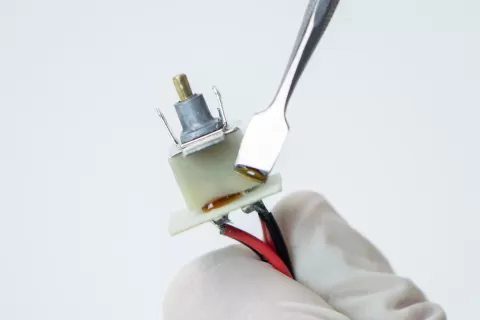

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ISO 10993-5 for Cytotoxicity

Meets EU Directive 2015/863

Packaging