EP62-1ND

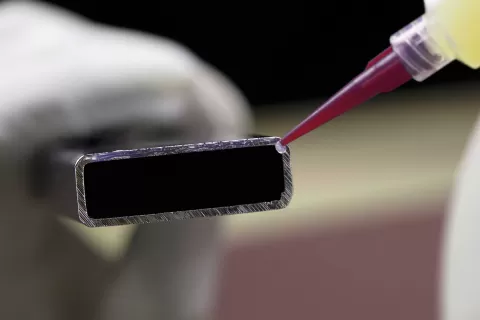

Two component epoxy resin system featuring excellent temperature and chemical resistance, non-drip application

Key Features

- Long open time at room temperature

- Cures rapidly at moderate temperatures

- Superb physical strength profile

- Reliable electrical insulation properties

Typical Properties

Viscosity

paste

Cure Schedule

4-6 hours at 140-158°F [60-70°C], 20-40 minutes at 176-212°F [80-100°C] or 10-20 minutes at 257°F [125°C]

Hardness

75-85 Shore D

Service Temperature Range

-60°F to +450°F

Tensile Lap Shear Strength

8,000-9,000 psi

Volume Resistivity

>10¹⁴ ohm-cm

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863