EP93FRHT

Two component epoxy system meets the Airbus standards noted below from ABD0031, Issue F, June 8, 2005 for flame retardancy

Key Features

- Twelve second vertical burn per AITM 2.0002B and Section 7.1.2 of ABD0031, Issue F

- Smoke emission per AITM 2.0007B, Issue 3 in the flaming mode and Section 7.3.2 of ABD0031, Issue F

- Toxic gas emission per AITM 3.0005, Issue 2 in the flaming mode and Section 7.4 of ABD0031, Issue F

Typical Properties

Viscosity

6,000-9,000 cps

Cure Schedule

overnight at 75°F followed by 3-5 hours at 150-200°F

Hardness

80-90 Shore D

Service Temperature Range

-80°F to +400°F

Dielectric Constant

4.5

Volume Resistivity

>10¹⁴ ohm-cm

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Airbus Standards for Flame Retardancy

Meets EU Directive 2015/863

Packaging

Video

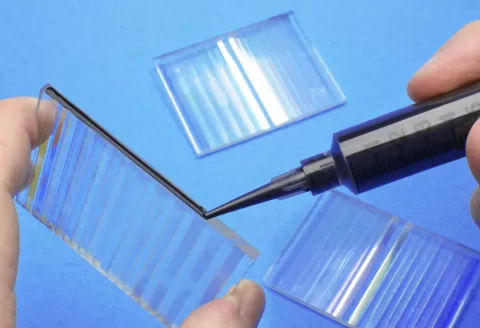

Product Spotlight: EP93FRHT

Specifically designed for avionic/aviation applications, Master Bond EP93FRHT readily passes the stringent Airbus specifications for vertical burn test, smoke emission and toxic gas emission as listed under ABD 0031, Issue F.

This video explain …