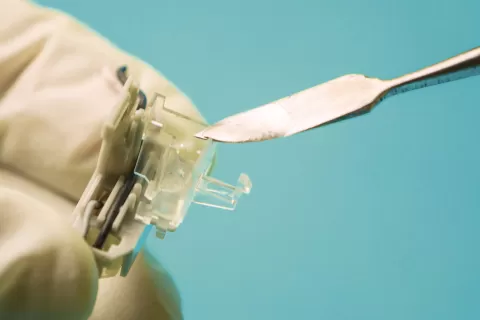

UV22DC80-10F

One component, nanosilica filled, dual cure system with UV and heat curing mechanisms

Key Features

- Thixotropic low viscosity

- Meets NASA low outgassing specifications

- Minimal shrinkage upon curing

- Cures at 80°C in shadowed out areas

Typical Properties

Viscosity

5,000-15,000 cps

Cure Schedule

Cures at 80°C in shadowed out areas; typically the UV portion occurs in 10-30 seconds at 365 nm with 10-40 milliwatts/cm2 of output; areas not cured because of shadowing effects can be readily cured at 80°C for 30-60 minutes; post curing at 125-150°C for 15-30 minutes will increase the To significantly.

Hardness

75-85 Shore D

Service Temperature Range

-100°F to +350°F

Glass Transition Temperature (Tg)

130-135°C

Refractive Index

1.52

Immagine