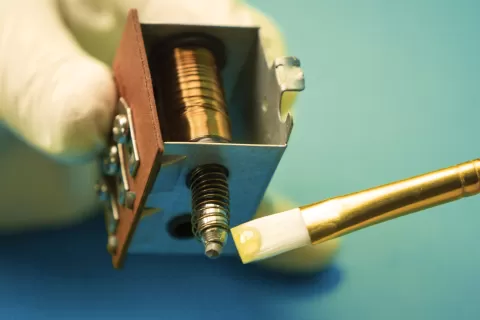

EP132

Two part epoxy for bonding featuring convenient processing and high temperature resistance

Key Features

- Flowable and thixotropic

- Very long open time

- Superior electrical insulation properties

- Excellent physical strength profile

Typical Properties

Viscosity

25,000-45,000 cps

Cure Schedule

2 hours at 125°C followed by 3 hours at 150°C; post cure of 3-4 hours at 350°F

Hardness

80-90 Shore D

Service Temperature Range

-60°F to +550°F

Dielectric Constant

3.29

Glass Transition Temperature (Tg)

205-210°C

Image