Comparison of Acetoxy Curing and Neutral Curing Silicones

One component condensation curing silicones are broadly classified into two main categories, acetoxy curing silicones and neutral curing silicones.

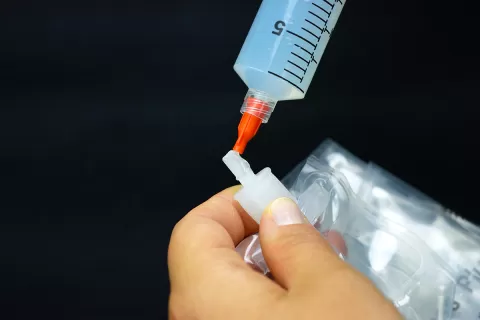

Acetoxy curing silicones derive their name because they release acetic acid upon curing. They typically cure fairly quickly, and relative to other silicones, tend to adhere better to various substrates. While the emission of acetic acid is acceptable in many industrial applications, if certain sensitive electronic components are present, the acetic acid emissions could potentially have an adverse effect on some of the components involved. While it is important to note that acetoxy curing silicones might be corrosive for certain substrates, they do offer many other advantages, and some of them are even biocompatible, making them useful for medical device manufacturing.

Some examples include:

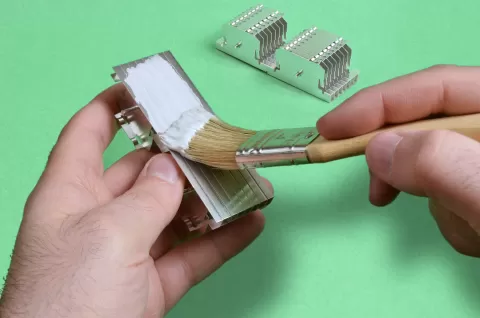

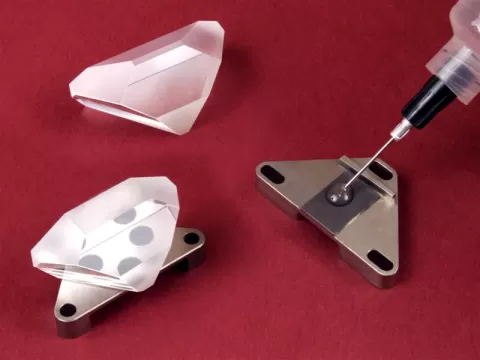

Neutral curing systems include the oxime and alkoxy silicones. Unlike the acetoxy system, methyl ethyl ketoxime is released with the oxime curing systems, and an alcohol is released with the alkoxy curing systems, and as such they are non-corrosive. Other neutral curing silicones might release acetone upon curing. These neutral curing silicones are extensively used as go-to products in electronic applications. In fact, Master Bond has gone one step further and started offering NASA low outgassing approved silicones. These unique systems are widely used in aerospace, electronic, and optical applications. Also, there are other neutral curing silicones which have been tested for biocompatibility as well.

Some examples include:

Featured Products in this Tech Tip