Supreme 10HT

One component, toughened epoxy system

Key Features

- No mix, single component system

- Serviceability from 4K to +400°F

- Unlimited working life at room temperature

- Resistance to mechanical and thermal shocks

- NASA low outgassing approved

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

>500,000 cps

Cure Schedule

60-75 minutes at 250°F; 35-40 minutes at 300°F

Hardness

70-80 Shore D

Service Temperature Range

4K to +400°F

Glass Transition Temperature (Tg)

130-135°C

Tensile Lap Shear Strength

3,600-3,800 psi

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

1,000 Hours at 85°C/85% RH

Meets EU Directive 2015/863

Packaging

Case Study

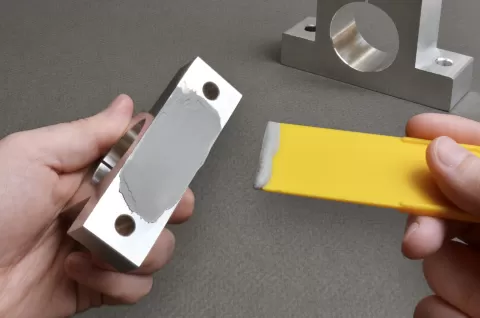

Supreme 10HT: Utilized in structural bonding for supersonic aircraft, electronics packaging and capacitor tanks

Because of its outstanding strength and other physical properties, Master Bond Supreme 10HT has been selected for use in several published research studies in the aerospace, electronics, OEM, materials science and more.