UV15DC80

One component, UV and heat curable epoxy compound with moderate viscosity

Key Features

- Allows for curing in “shadowed out” areas

- Cures at temperatures as low as 80°C

- Convenient no mix system

- Excellent physical strength properties

Typical Properties

Viscosity

45,000-60,000 cps

Cure Schedule

10-20 seconds with UV light at 365 nm with 20-40 milliwatts/cm2 of energy; areas not cured by shadowing can be cured at 80°C for 2-3 hours; post curing for 2-4 hours will help optimize properties; if possible, 1-2 hours at 125°C will promote curing even further

Hardness

>70 Shore D

Service Temperature Range

-80°F to +350°F

Glass Transition Temperature (Tg)

125-135°C

Volume Resistivity

>10¹⁴ ohm-cm

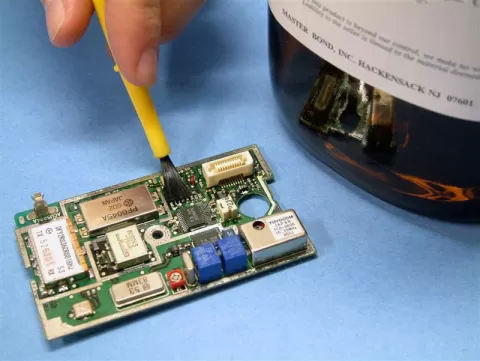

Image

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

Case Study

UV15DC80: Utilized in ultraviolet-assisted three-dimensional printing

Researchers at Ecole Polytechnique de Montreal manufactured photopolymer-based microdevices with 3D self-supported and freeform structures. The investigated photopolymers included a polyurethane-based resin and Master Bond UV15DC80.