Infographic Page

Newly Developed Products 2017 - Part 1

Browse though Master Bond's product highlights of 2017! These adhesives, sealants, coatings and encapsulation systems feature unique performance properties and many meet stringent industrial specifications.

Featured Products

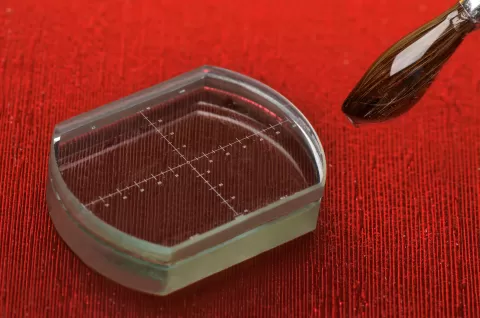

Immagine

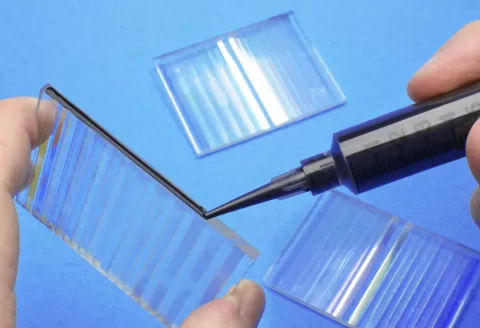

Low viscosity epoxy for large potting/encapsulation applications. Low modulus, high elongation. Long working life. Exceptionally low shrinkage upon cure. Impressive optical clarity. Low exotherm. Serviceable from -60°F to +250°F.

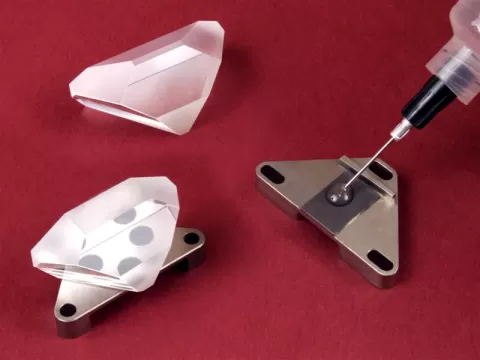

Immagine

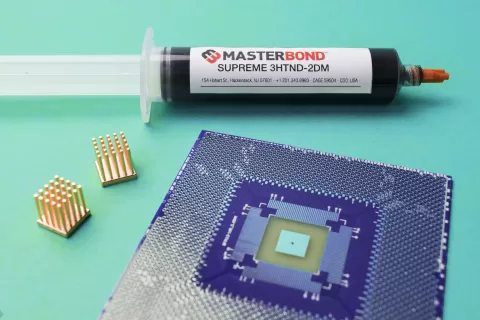

Silver coating nickel filled electrically conductive epoxy adhesive has a rapid cure speed. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive. Smooth paste, consistency. Dispensible from syringe applicator. Serviceable from -60°F to +400°F.

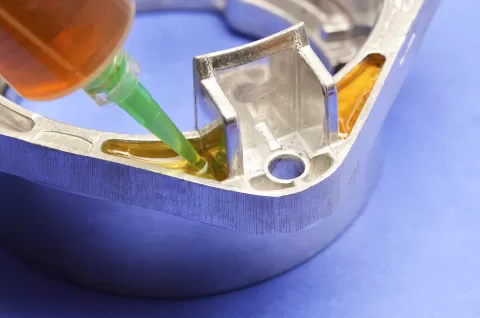

Immagine

Cures rapidly at moderate elevated temperatures. Superior resistance to harsh chemicals. Two part epoxy has long pot life at ambient temperatures. High bond strength properties. Reliable electrical insulator. Serviceable from -60°F to +500°F. Tg 170-175°C. Shore D hardness 80-90.

Immagine

Two part epoxy system that passes Airbus specifications for flame resistance, smoke density and toxicity. Bonds well to a variety of substrates including metals, composites, glass, ceramic and many plastics. One to one mix ratio by weight. Moderate viscosity. Service operating temperature range from -80°F to +400°F. Excellent electrical insulator. Non-halogenated system.

Immagine

Rapid curing, one part epoxy. Meets USP Class VI biocompatibility standards. Non-drip, paste viscosity. High shear strength. Superb resistance to autoclaving, chemical sterilants, radition, EtO. Serviceable from -60°F to +400°F.

Immagine

Toughened epoxy paste system for damming applications. Requires no mixing. Rapid heat curing. Passes NASA low outgassing testing. Transfers heat efficiently. Stellar electrical insulation properties. Serviceable from -100°F to +400°F.