Master Bond EP29LPHE is a two part epoxy that cures somewhat hard, but has very notable toughness along with high elongation. It can be used for bonding, coating, sealing and encapsulation. This low viscosity system has a forgiving mix ratio of 100 to 80 by weight. The working life of a 100 gram mass is exceptionally long, 12-24 hours. EP29LPHE will cure at ambient or elevated temperatures (see below). The optimum cure schedule is 12-24 hours at room temperature, followed by 4-5 hours at 140-180°F. Upon curing, this epoxy system, as noted above, combines good strength and toughness.

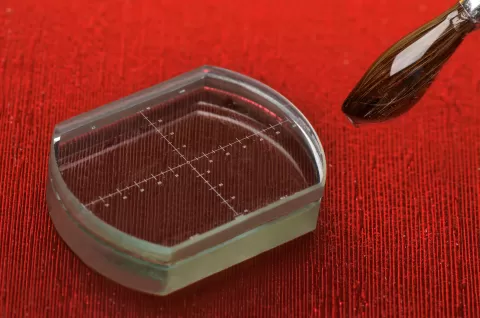

The system bonds well to a wide variety of substrates including metals, ceramics, glass, optical fibers, polyimide, graphite and many rubbers and plastics. EP29LPHE has an unusual array of physical properties. Although it cures relatively hard, it has high elongation that imparts good impact and shock resistance. It also allows it to be used in applications where thermal cycling and resistance to vibration and shock are important requirements. It is a dependable electrical insulator, which, when combined with its low viscosity and low exotherm, permits it to be particularly well suited for large casting applications. EP29LPHE has reasonably good chemical resistance to water, acids, bases, oils and fuels. Part A is amber and Part B is amber-opaque in color. Its versatility allows it to be used in a number of diverse applications including aerospace, electronic, specialty OEM and related industries where this special set of product properties is desirable.

Product Advantages

- Convenient, non-critical 100 to 80 mix ratio by weight

- Very low viscosity, exceptionally long working life

- Special physical strength profile, combining toughness, hardness and elongation

- Notable electrical insulation characteristics; ideal for larger potting and encapsulation applications

- Desirable adhesive for composites, optical fiber, fiber-reinforced materials

- Exceptionally low shrinkage upon curing