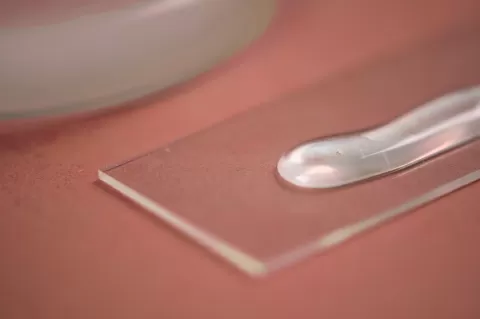

Master Bond UV21 is an easy to use one component UV curable system for high performance bonding, coating, encapsulation and formed-in-place seals and gaskets. Its most salient properties are its astounding flexibility and very low Shore A hardness. It should be noted that this is not a silicone based system and it is a very good adhesive. It bonds well to a wide variety of substrates including glass, polycarbonates and acrylics as well as various plastics and many metals. It has a terrific ability to withstand rigorous thermal cycling and shocks. UV21 is a first rate thermal and electrical insulator. Its pronounced softness allows it to be more easily reworked when compared to most other UV systems. Its temperature range is -65°F to +250°F.

Master Bond UV21 generally cures readily in 10-30 seconds when exposed to a UV light source emitting at a wavelength of 320-365 nm with an energy output as low as 20-40 milliwatts/cm². The rate of cure depends upon the system’s distance from the light source, the thickness of the section and of course the intensity of the light source. It should be noted that the system can cure in sections approaching 1/4 inch thick. However, when bonding, sections of a few thousandths of an inch are more than adequate. Most importantly UV21 does not display oxygen inhibition. UV21 can be used in many types of optical, aerospace, specialty OEM, fiber-optic and electronic applications where fast curing, very significant flexibility and/or if repairability are desired.

Product Advantages

- One component system; no mixing needed

- Exceptionally fast cure upon exposure to a UV light source at ambient temperatures

- No oxygen inhibition while curing; no special inert atmosphere required

- Very high flexibility, capable of withstanding the most aggressive thermal cycling and shocks

- Deluxe electrical and thermal insulator

- Wonderful optical clarity; excellent light transmission

- Very good reworkability