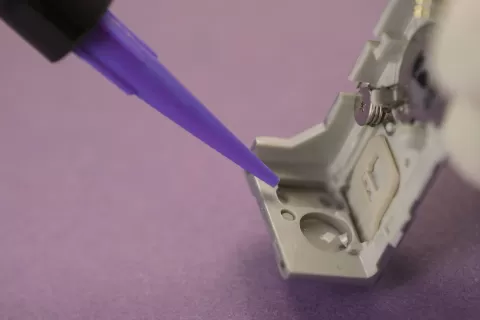

UV22DC80-1Med

One component, nanosilica filled, dual cure system with UV and heat curing mechanisms passes ISO 10993-5 for cytotoxicity and USP Class VI

Key Features

- Low viscosity

- Minimal shrinkage upon curing

- Superb optical clarity

- Cures at 80°C in shadowed out areas

Typical Properties

Viscosity

500-3,500 cps

Cure Schedule

UV light 320-365 nm for 20-30 seconds, followed by 80°C for 1 hour

Hardness

80-90 Shore D

Service Temperature Range

-60°F to +350°F

Dielectric Constant

3.85

Glass Transition Temperature (Tg)

120-130°C

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ISO 10993-5 for Cytotoxicity

Meets EU Directive 2015/863

USP Class VI Medical