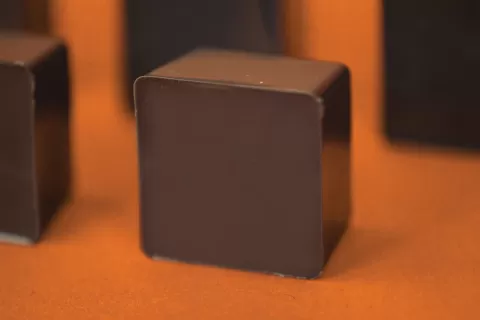

EP76MHT

Two component, nickel filled epoxy for bonding, sealing and coating

Key Features

- Good electrical and thermal conductivity

- Highly serviceable operating temperature

- Convenient processing

- Excellent dimensional stability

Typical Properties

Viscosity

>700,000 cps

Cure Schedule

overnight at ambient temperature followed by 3-4 hours at 150°F

Hardness

>80 Shore D

Service Temperature Range

-60°F to +400°F

Coefficient of Thermal Expansion

30-35 X 10⁻⁶ in/in/°C

Glass Transition Temperature (Tg)

85-90°C

Tensile Lap Shear Strength

>2,100 psi

Thermal Conductivity

8-9 BTU•in/(ft²•hr•°F)

Volume Resistivity

5-10 ohm-cm

Image