MasterSil 922-LO

One part, low outgassing silicone for bonding, sealing, coating & encapsulation

Key Features

- Meets NASA ASTM E595

- Neutral type cure

- Paste consistency

- Excellent performance profile

Typical Properties

Viscosity

paste

Cure Schedule

Recommended cure time, 75°F: 7 days

Hardness

40-50 Shore A

Service Temperature Range

-175°F to +500°F

Elongation

250-350%

Tensile Modulus

200-300 psi

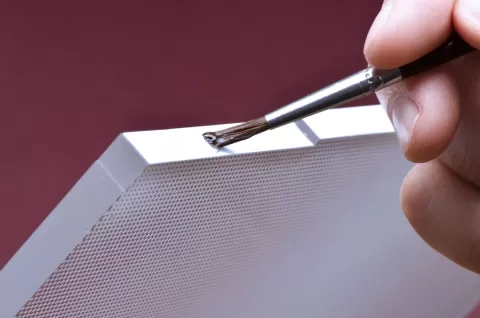

Image

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Packaging