Supreme 45HTND-2

Toughened, two component epoxy system for bonding, sealing and coating

Key Features

- Outstanding temperature resistance

- Superior thermal cycling capabilities

- Excellent electrical insulator

- Non-drip application feature

- Very good peel strength

- Exceptionally long working life

Typical Properties

Viscosity

paste

Cure Schedule

250-300°F for 3-4 hours

Hardness

80-90 Shore D

Service Temperature Range

-100°F to +450°F

Dielectric Constant

4.5

Tensile Lap Shear Strength

>2,500 psi

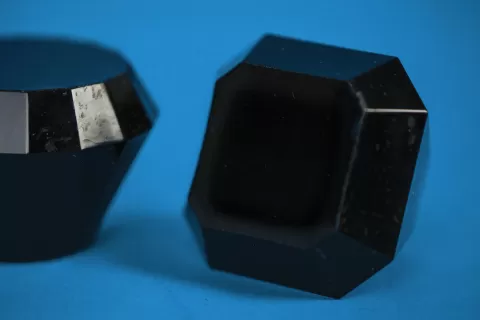

Image