EP15ND-2

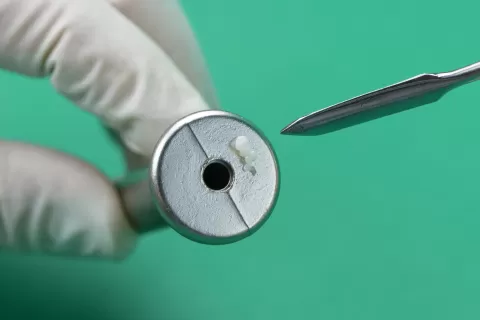

One part epoxy for testing adhesion or cohesive strength of metallic based flame-sprayed coatings

Key Features

- Used in ASTM C633 testing applications

- Exceptionally high tensile strength

- Non drip

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

paste

Cure Schedule

300-350°F for 60-90 minutes

Hardness

80-90 Shore D

Service Temperature Range

-60°F to +250°F

Tensile Strength

12,000-14,000 psi

Tensile Lap Shear Strength

2,600-2,800 psi

Image

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

Case Study

EP15ND-2: Used in a Comparison of Tests Evaluating the Bond Strength of Thermal Sprayed Coatings

Master Bond EP15ND-2 is a single component, heat curing epoxy specifically designed for testing the strength of thermal sprayed coatings as indicated by ASTM C633. Featuring exceptionally high tensile strength exceeding 12,000 psi, as well as unlimit …