UV15TK

Moderate viscosity, one component, UV curable epoxy based system

Key Features

- Good flow, but not too watery

- Resists up to 400°F

- Cationic curing system

- Excellent physical strength properties

Typical Properties

Viscosity

6,000-12,000 cps

Cure Schedule

UV light 320-365 nm for 15-30 seconds

Hardness

>75 Shore D

Service Temperature Range

-80°F to +400°F

Refractive Index

1.517

Volume Resistivity

>10¹⁴ ohm-cm, 25°C

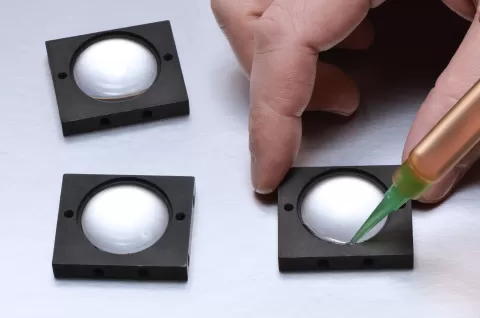

Image

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

Case Study

UV15TK: for 3-D Printing of Reverse Osmosis Feed Spacers with Reduced Scaling Effects

Master Bond UV15TK was selected for use as a 3-D printing material to directly print micromixer elements of an optimal design onto the semipermeable membrane for a reverse osmosis feed spacer.